These 6 benefits will help you know why Fiber Laser is important for Deep Etching Metal.

A lot of companies focus on increasing their commercialization which is important in today's age where a new yet similar servicer is arising. There are many benefits to taking laser services. A diverse range of market is in existence that needs deep engraving fiber laser services which come from laser automation.

When fiber lasers came in the market, very few realized the potential of improving industries the way they thought to be. But as time changed where alongside gas lasers, it also gained its importance and market share.

If your searches for "Deep Etching Metal With Fiber Laser Automation" has not provided you anything significant then Worldwide Laser Service Corporation is what you should be visiting for.

If you look at laser marking in comparison to ink-based marking then you would see that the former is more environmental-friendly, are deftly automated, less exhaustive. The arrival of Fiber Laser Automation has solved the problem of many industries, enterprises, manufacturers that relied on the other laser services that were not up to the mark and were nowhere to what the fiber lasering turned out.

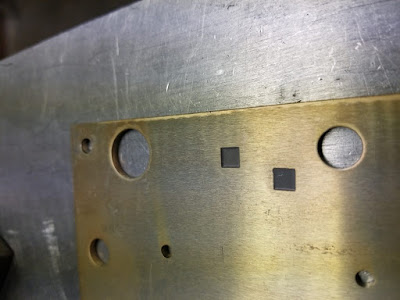

The usage of Fiber Laser Automation services is seen while marking plastics and welding metals. They have helped those industries significantly. If you are one such an industry that uses these laser services then you know how versatile, approachable, and economical they are in their end-products or end-services. If you are still unconvinced by these benefits, we suggest you book an appointment with professionals and laser specialists at WLSC. They will help you understand how laser services by deep etching steel/metal are important and significantly increase your company's commercial angle.

Following are the major benefits that are covered by "Deep Etching Metal with Fiber Automation". These merits can be only be utilized if you opt for a particular series of laser automation as each one of them brings different results.

- Reducing metal fatigue by eliminating mechanical striking or scribing systems.

- The level of protection is high for all kinds of products, consumers, and manufacturers.

- You don't have to go for long procedures when it comes to regulatory requirements regarding depth and permanence of metal parts identification.

- The production time and labor costs are greatly reduced.

- There is hardly any presence of residue, scraps, and useless supplies.

- You have an eco-friendly green manufacturing environment service for your company/industry.

When it comes to laser services and deep cut engraving methods, nobody is as punctilious and outcome-driven as WLSC. WLSC which stands for Worldwide Laser Service Corporation is one of the leading laser automation and laser system integration service providers. Their services are present in the market since 1986 for they have stood out with their expeditious results.

A lot of companies and industries such as automotive, Jet engine assembly, aerospace, Dental implants, Tool and die making, Jewelry repair, 3D marking, electronics, medical and semiconductors among others are using laser services in best ways possible. Their main branch is located in the USA which is precisely at 1340 W San Pedro St, Gilbert, AZ 85233, USA.

Comments

Post a Comment